2017 OKUMA MULTUS B200II

No longer available

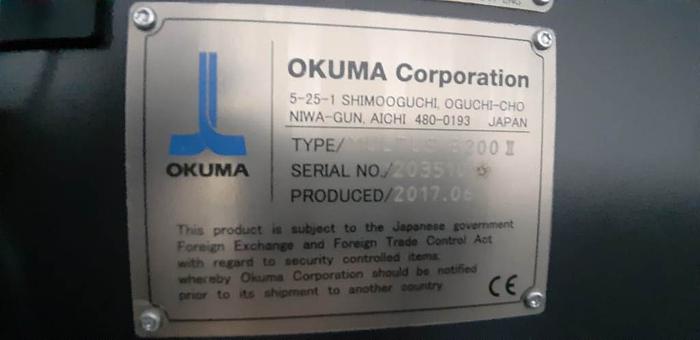

2017 OKUMA MULTUS B200II

Location:Livonia, MI

Description

OKUMA Intelligent Multitasking Model MULTUS B200II (W} with OSP-P300S CNC Controller (15 inch OSP suite) Including CE mark 2017

Standard Specification

Main spindle motor PREX 11/7.5kW (20 min./cent)

Main spindle speed, 50 .. 6,000 min-1, (Auto two-shift,PREX) Main spindle 140flat, bore dia. 62mm

C-axis control, 360 degree at 0.001degree increment

No chuck & no tube for Main-Spindle

Hollow cylinder SR1146 for main spindle, not incl. draw tube

Y-axis stroke 160mm (+80mm- -80mm)

H1 ATC turret HSK-A63

Max tool weight: 4kg Max tool length: 200mm (from gauge line)

20-tool ATC

Rotary tooldrive motor. VAC 12/8 kW ( 5 min./cont) Rotary tool spindle speed, 50- 12,000 min-1

Sub spindle motor PREX11/7.5KW(20min./cont.)

Sub spindle speed, 50- 6,000 min-1, (Auto two-shift, PREX) Sub spindle 140flat, bore dia. 62mm

No chuck & no tube for Sub-Spindle

Hollow cylinder SR1146 for sub spindle, not incl. draw tube

Chuck air blower for main + sub spindle

Hydraulic power unit

"Pre-arrangement for High pressure coolant unit 7MPa

UM through spindle coolant pressure high/low switchable function

(High/Low pressure pumps and filter unit will be arranged locally)"

Pump for Chip flusher and ExternalM-spindle coolant:0.8kW(MTH2-50/5)

+Pumping pump:0.88kW(MTH4-4013) Totally enclosed chip and coolant shield Door interlock

Work light, LED, left and right each

Foundation washers and leveling jack screws

Machine lifting hooks & hand tools

Chuck auto open I close with confirmation for main + sub spindle

M spindle through coolant supply spec. S-axis indexing, 0.001 degree indexing Lubrication monitor A-1+ Hydraulic original Chip pan

Application for IEC standard

Touch setter M

Double type chuck operation pedal

CE mark and EMC Dummy holder HSK-A63

OSP-P300S 3D-M-E kit specifications

*Workpiece coordinate system selection 10 sets

*Coordinate conversion

*Profile generation

*Coordinate computation (including NYCL command)

*Coordinate change: shift, rotate, copy

*Real 3D simulation

*Cycle time over check

*Load monitor (spindle, feed axis)

*NC operation monitor (incl. counter and totalization function) "Signal tower 2 colours

*Spindle speed modulation control

*Cycle time reduction function

*Hi-Cut Pro

Colour 15" touch display

Thermo-Friendly Concept (H1 TAS-S and TAS-C)

Collision Avoidance System

Toolcompensation* Implemented as "simple operations" functions

Workpiece jump out detection

Electrical Power Source Application to suite local power source at each countries

Specifications

| Manufacturer | OKUMA |

| Model | MULTUS B200II |

| Year | 2017 |

| Condition | Used |