2009 MIYANO ABX-51TH2

No longer available

2009 MIYANO ABX-51TH2

Location:Livonia, MI

Description

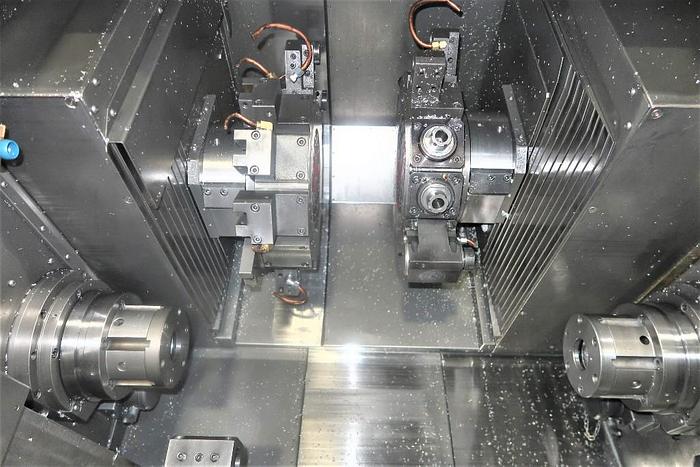

MIYANO MODEL ABX-51TH2 10-AXIS TWIN SPINDLE 3 TURRET

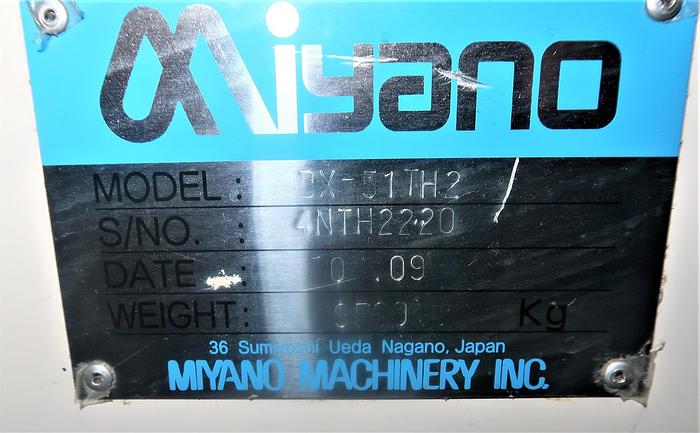

Manufacturer: Miyano

Model: ABX-51TH2

Year: 2009

Specifications

Machining Capacity:

Standard Turning Length 125mm

Max. Bar Diameter (Main Spindle/Sub Spindle) 51mm/51mm

Max. Power Chuck Size (Main Spindle) 6"

Max. Power Chuck Size (Sub Spindle) 6"

Axis Travel:

HD1-Upper Turret

X1-Axis 190mm

Z1-Axis 257mm

Y1-Axis +/- 40mm

HD2-Lower Turret

X2-Axis 190mm

Z2-Axis 500mm

HD3-Upper Turret

X3-Axis 190mm

Y3-Axis +/- 40mm

Z3-Axis 650mm

Spindles:

Number of Spindles 2

Spindle Nose (Main/Sub Spindle) A2-6

Spindle Speed Range (Main/Sub Spindle) 50-5000 RPM

I.D. Draw Tube (Main/Sub Spindle) 52mm

Chuck Cylinder; Hydraulic Rotary Hollow Cylinder

Collet Chuck for Left: Spindle (collets not includ) DIN 177E

Collet Chuck for Right Spindle (collets not includ) DIN 177E

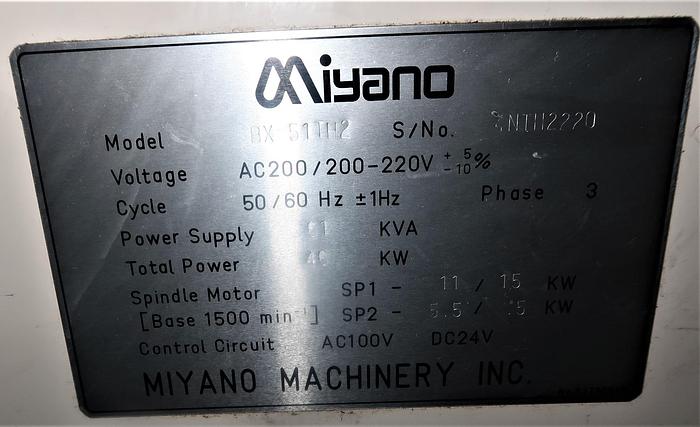

Spindle Motors:

Left Spindle: 15/11Kw cont./30 min

Right Spindle: 7.5/5.5Kw

cont./30 min

Turrets:

Number of Turrets 3

Number of Turret Stations:

Upper Turret HD1/HD3 & Lower Turret HD2 12

Main & Sub Spindle Positioning: "C" Axis

(Spindle orientation to both Main & Sub Spindles)

Revolving Tools:

Number of Rotating Tool Stations:

Upper HD1/Upper HD3 12

Lower HD1 12

Speed Range:

Upper HD1/Upper HD3 40-4000 RPM

Lower HD1 40-4000 RPM

Machine weight (approx) 20,944

Equipped With

(Standard accessories)

12 Station Upper Turrets HD1 & Hd3 & 12 Station Lower Turret HD2

Fanuc VAC 15 kw/11 kw for Main Spindle & VAC 7.5 kw/5.5 kw for Sub Spindle.

C Axis Control to Main & Sub-Spindles

Y Axis Control to Upper Turret HD1 and Upper Turret HD3

Tool Setter for HD1, HD2 and HD3

Automatic Lubricating System

Coolant System

Hydraulic equipment, Hydraulic Rotary Cylinder for Main & Sub Spindles

Chuck Close/Open Confirmation Switch for Main & Sub Spindle

Splash Guard with Door Interloock System

Machine Light, Pneumatics Unit

Spindle Assembly for DIN 177 E for Main & DN 177E Sub

Inner Coolant, Cylinder-type Work Ejector and Air Blow for Sub Spindle

Servo Driven Parts Catcher for Main & Sub Spindles

Parts Conveyor, High Pressure Coolant for Upper & Lower Turrets (HD1,HD2 & HD3)

High Pressure Coolant for Upper & Lower Turrets (HD1,HD2 & HD3)

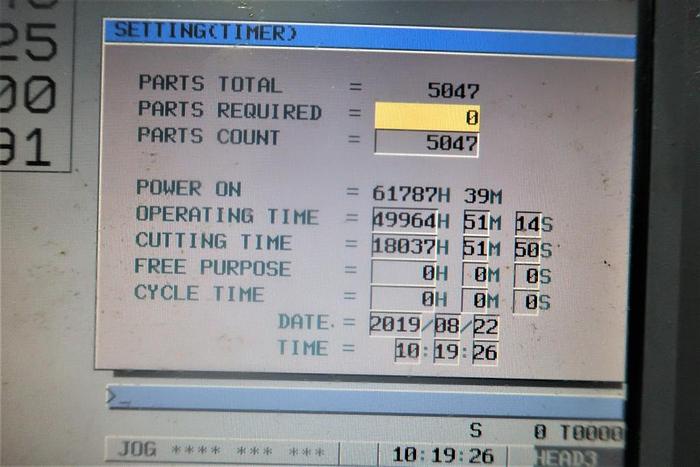

Total & Pre-Set Counter, Manual Retrace Function

Filler Tube Assembly, Signal Tower 3-Step,

Double Spindle Orientation

Revolving Tool Drive Unit for Upper & Lower Turrets (HD1, HD2 & HD3)

Cut-off Confirmation - Electrical Type

Cut-off Confirmation - Mechanical Type

Auto Power Shut Off, Coolant Level Switch

Coolant Level Switch

Chip Conveyor-Hinge type for General purpose Usage-Outlet Ht. 1Metre

Disc Brake to both Main & Sub Spindle

Tool Monitoring System (Inc Fanuc N.C. Option and Miyano Software)

Tooling Package:

Miyano Recommended Set of toolholders

Turning Tool Holder A & B

Bar Feed Interface

Fanuc 31i-TA Control:

Constant Surface Speed Control

Multiple Repetitive Cycles

Chamfering/Corner R Compensation

Tool Nose Radius Compensation

Inch/Metric Conversion

Geometry and Wear Offsets

Polar Coordinate Interpolation

Cylindrical Interpolation

Parts Program Storage Length 320m

Background Editing

Rigid Tapping Function with Custom macro B for Revolving Tools

Rigid Tapping Function for Main & Sub Spindle

Direct Drawing Dimension input

Extended part Program Editing

Alarm Display, G10 Function, Overlapping Function for HD2, HD3 & Sub Spindle

Helical Interpolation, Polygon Turning, Run Hour/Parts Number Counting

Synchronous Mix Control

500 Sets of Program Counting

Note: New Replacement Price Exceeds $600,000.00 Today

Specifications

| Manufacturer | MIYANO |

| Model | ABX-51TH2 |

| Year | 2009 |

| Condition | Used |